There are two basic methods of extracting coal: surface mining and underground mining. Surface mining is typically used when the coal is less than 60 meter below the surface. To gain access to the coal deposit, large-sized mining machines are used to remove the top layers of soil and rock. The coal is then excavated and transferred to a preparation plant for cleaning to remove dirt, rock, ash, sulfur, and other unwanted materials, increasing the heating value of the coal. The coal may also be sorted by quality and size. After the mining operation is completed, the soil and rock are brought back to fill the mine. The area is then revegetated and can be used for other purposes, such as farming, wildlife conservation, recreation, or other commercial or industrial projects.

Right Machine for the Job

EIK amphibious excavators have a well-established presence in the mining sector, helping mine operators and contractors tackle ongoing challenges related to dam tailing, dewatering, flooding, and more. Mining sites particularly in the tropical region have to endure months of reduced production and gruelling operational challenges during the monsoon season each year. Each monsoon season can stretch up to a period of 5 months, and loss in productivity is hefty especially when the commodity price is on a bull run.

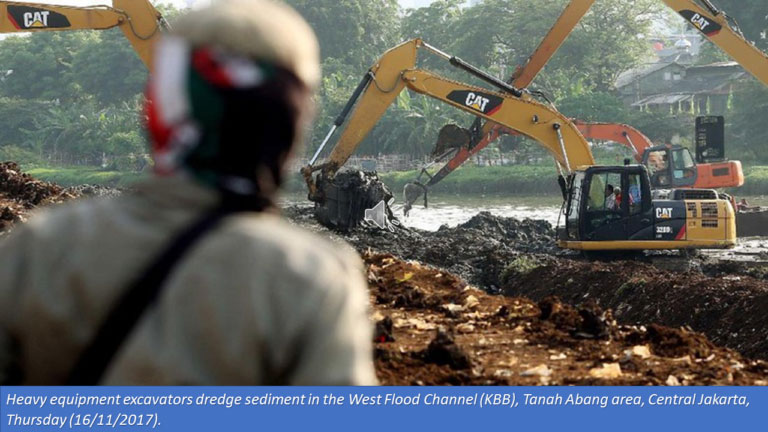

Consider the case of a mine site concentrating on crushed steam coal and other high-grade coal for industrial applications. The open pit mine operation has to deal with the aftermath of annual flooding during the monsoon period. Due to the nature of the site and its surrounding terrain, deluges of waterborne debris such trees and logs from higher ground can flood the pit in a matter of hours. These unwanted debris, coupled with thick layers of mud, pose significant challenges in the dewatering process by clogging up the water pump, and frequent stoppage is necessary to service and maintain equipment. Simply put, the clearing process is slow and punishing.

Conventionally, the two most common methods are to deploy long reach excavators at the pit fringe, as well as to build temporary access trails. Both solutions are far from ideal. Long reach excavators can only clear up to 20m from the edge; constructing temporary access trails for excavators is time-consuming and costly due to the size of the pit, and they have to be subsequently deconstructed. During this time, there are forty articulating trucks, twelve units of 80-ton class excavators, two 120-ton excavators, and five 50-ton excavators basically semi-idling.