Available in various models to suit excavator sizes ranging from 5 – 30 metric tons (11,000 – 66,000 lbs) operating weight. The fork grapple is popular among customers who seek to reduce cycle time as their top priority.

DESIGN

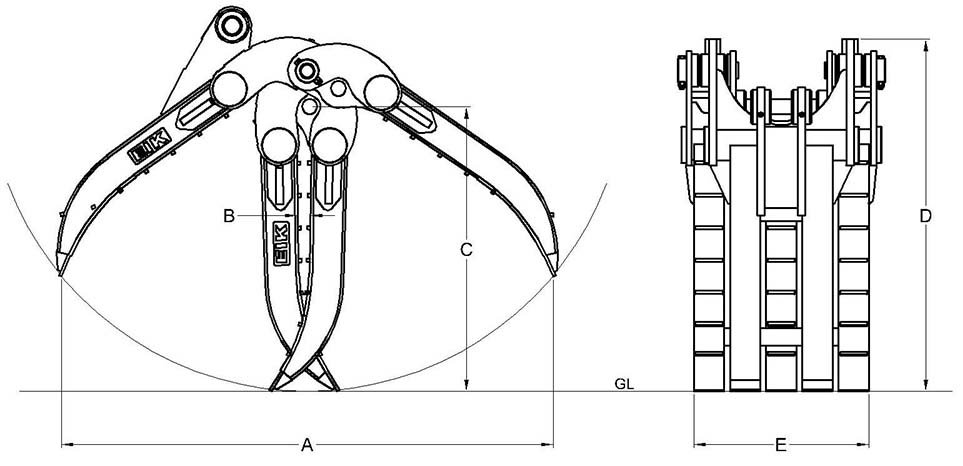

Fork Grapple is a relatively new design under the Grapple family. The design was tweaked from a conventional grapple for material handling applications, light demolition, recycling and scrap industries. Its lightweight, 2-tine over 3-tine frame design provides extraordinarily rapid grappling action, reducing cycle time and increasing productivity. Internal structures within each tine are heavily reinforced to ensure maximum rigidity.

Unlike the conventional grapple design where a stiff arm is mandatory, in the case of a fork grapple, the use of stiff arm is totally eliminated. As a result, both jaws open and close simultaneously in a single action, which translate into 2x the opening and closing speed of jaws as compared to typical stiff-arm grapple, and yet with a very firm clamping force. Each tine is serrated with wear strips, provides additional protection on each tine as well as enhancing the gripping strength of irregularly shaped items.

Here are the key specifications for this product model.

Want to know more? Download the brochure or contact us.

| A | B | C | D | E | |||

|---|---|---|---|---|---|---|---|

| Model | Excavator Class | Approximate Weight | Max Jaw Opening | Min Gap Between Jaws | Length of Tines | Height | Width |

| FC46 | 6,600 – 11,000 lb | 630 lb | 48 inch | 1.0 inch | 28 inch | 35 inch | 19 inch |

| FC56 | 13,200 – 17,600 lb | 792 lb | 67 inch | 1.2 inch | 37 inch | 46 inch | 21 inch |

| FC76 | 19,800 – 26,400 lb | 1,100 lb | 76 inch | 1.6 inch | 41 inch | 51 inch | 29 inch |

| FC88 | 39,600 – 46,200 lb | 1,727 inch | 90 inch | 2.0 inch | 52 inch | 64 inch | 32 inch |

| FC98 | 52,800 – 63,800 lb | 2,592 lb | 113 inch | 2.5 inch | 67 inch | 83 inch | 34 inch |

*Dimensions are for reference only, it may vary from excavator brands and models.

** For the benefit of continuous product improvement, specifications are subjected to change without prior notice.

Demolition of wooden structure/house.

Handling of industrial material.

Land clearing and garbage handling.

Waste recycling and scrap handling.

- Extremely easy to install, no welding process is needed. Similar assembly process as a bucket.

- Large jaw opening, increased productivity.

- Upper and lower jaws open and close simultaneously, translate to a higher operation speed and improves productivity.

- Reinforced internal tine structure, designed for high durability.

You Might Also Like

FIND YOUR RIGHT SOLUTION WITH EIK ENGINEERING

At EIK Engineering, we are committed to the delivery of quality amphibious excavators and excavator attachments. Please fill out the form below to get in touch with us! We’ll get back to you as soon as we can.