EIK places great emphasis on innovation and quality manufacturing to meet your construction equipment and attachment needs.

In 2010, we have relocated to a new facility and invested heavily in state-of-the-art machinery, increased human resources to further improve our productivity and yield, enabling us to deliver higher quality products while rewarding our customers. We continue to invest in our R&D human capital and software to propel us to develop new and sophisticated products to meet the everchanging market demands.

With multiple facilities totaling about 300,000 sq feet of floor space, our facilities are relentlessly turning out products for the world. Every finished product comprises the pride and determination of our 300 employees. Our facilities are strategically located at the southern tip of West Malaysia, a mere 5 minutes’ drive across the Singapore border.

This location is ideal for manufacturing heavy equipment where wide open spaces are a requirement. And more importantly, the location gives easy access to world-class container terminals within a 50km radius in both Singapore and Malaysia. Frequent vessel schedules ship to every part of the globe which enables us to deliver our products with a short lead time.

Robotic Welding for Long Reach

- The robot welding machine is used to perform arc welding and handling parts.

- Robotic welding helps with minimising human error, scrap and improving the efficiency of the welding process.

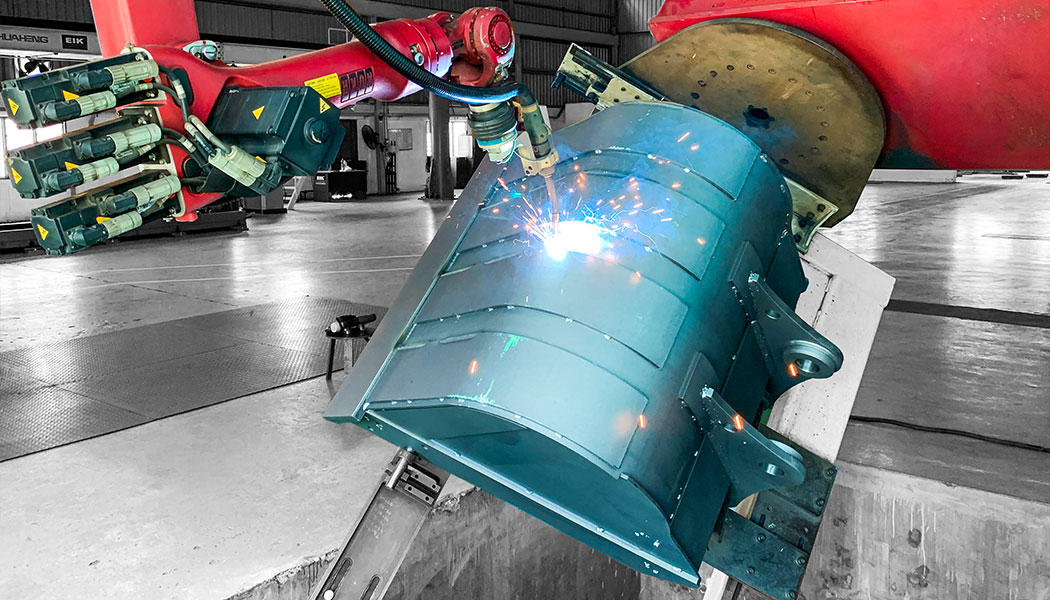

Robotic Welding for Bucket

- The robot welding machine is used to perform arc welding and handling parts.

- Robotic welding helps with minimising human error, scrap and improving the efficiency of the welding process.

Auto Shot Blasting

- The auto shot blasting machine is used to remove the surface contaminant, clean and roughen a smooth surface before painting or coating process.

CNC Laser Cutting Machine

- All steel materials are processed by CNC machines by controlling a high-powered laser beam. The laser beam then cuts the material, leaving the edge with a high-quality finish.

- This process ensures a high level of precision and consistency throughout the materials we use for manufacturing.

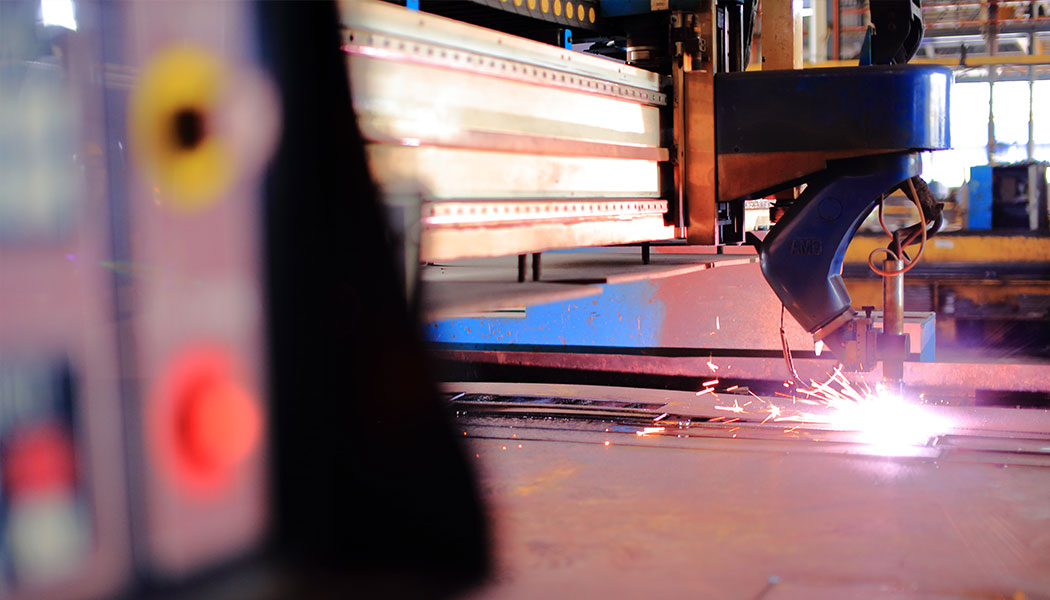

CNC Plasma Cutting Machine

- Plasma cutting is a process that is used to cut steel with different thicknesses (thicker steel material which cannot be processed by laser cutting) using a plasma torch.

- In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma.

- The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut.

CNC Milling Machine

- High standard of milling precision to flat-surface hand-engraving work.

Multi Axis Machining Center

- CNC-Line Bore Machine provides perfect alignment at the highest attainable precision.

- It can ensure the minimum tolerance misalignment of only 0.01%.

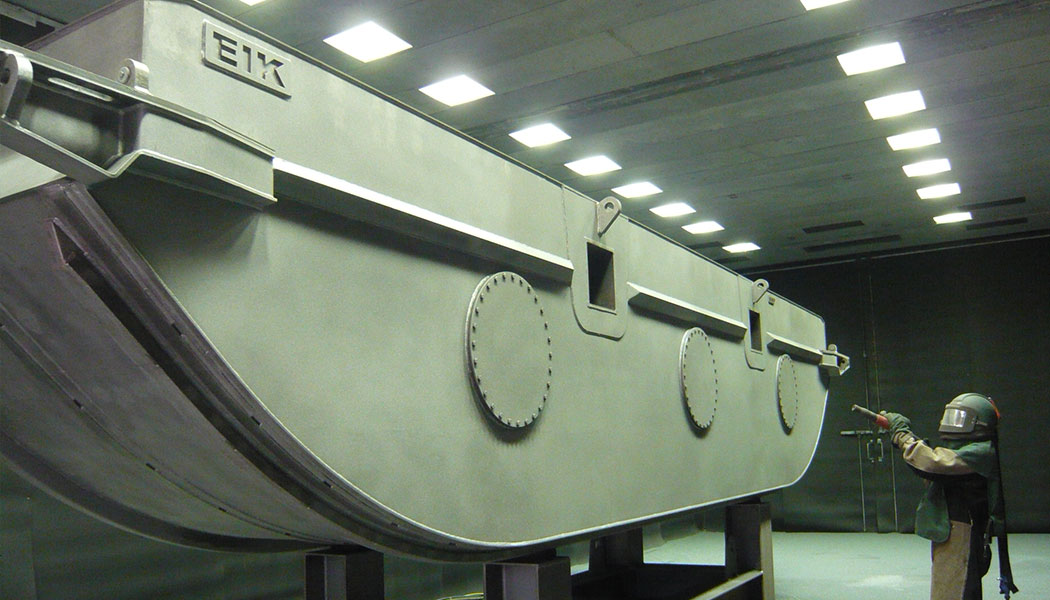

Sand Blast Chamber

- Operation of forcibly propelling a stream of abrasive material against a surface under high pressure to roughen a smooth surface and remove surface contaminants.

- Steel surface is thoroughly clean and free from contaminants and rust.

- Sand blast process create a rough steel surface texture that provide excellent cohesion for paint coating.

3D Tube Bending Machine

- This machine is used to ensure high precision and accuracy of turning angle.

- A smooth rounded bend can be created.

- The machine is able to achieve high productivity and efficiency.

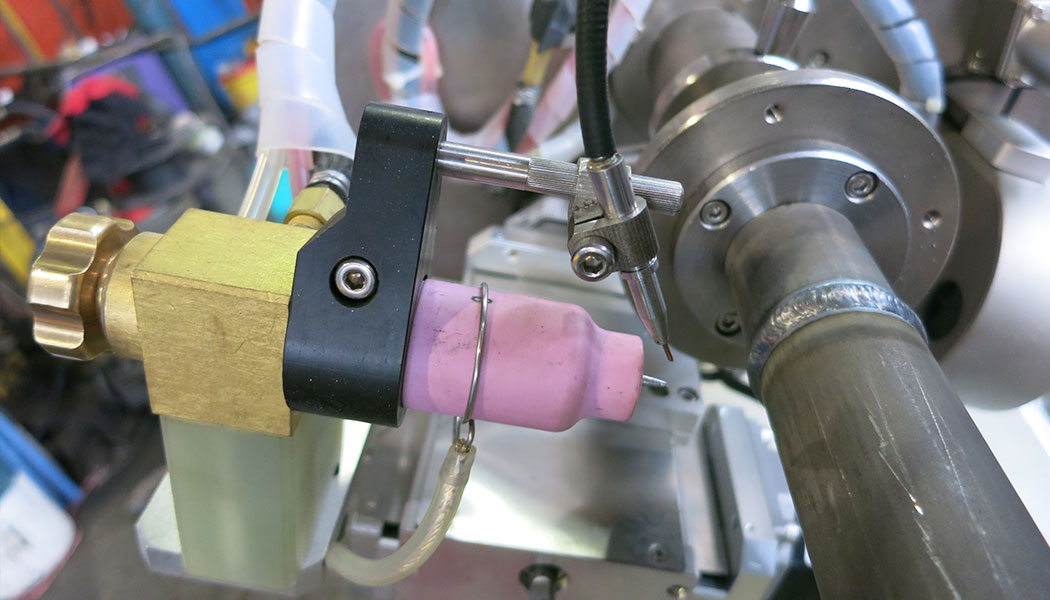

Robotic TIG Welding

- Hydraulic lines are TIG welded.

- This machine is used to achieve a precise and high-quality weld.

- Low contamination and cleaner joints can be achieved by using this TIG Orbital Welding Machine.

Industrial Grade Painting Room

- We apply premium epoxy paint for both undercoat and final coat.

- Epoxy paint offers superior adhesion and protection on steel against harsh environments.

- Painting process is carried out in an industrial grade paint room with a powerful filtration system.

- Minimising trapped foreign particles to ensure a high level of coating finishing.