AMPHIBIOUS SERIES

Amphibious Excavator

Want to know more? Download the brochure or contact us.

An amphibious excavator/marsh buggy is specifically designed to manoeuvre in marshy, swampy area and soft terrain, and it can also float on water as an added safety feature. It is completely self-propelled and can virtually access all terrains, and yet requires minimum supporting transportation and hoisting equipment. Thanks to our patented ‘multi-synchronous direct drive‘ system, a pivotal technology developed by EIK that positions us at the forefront of amphibious excavator design. We are now the largest full range (7 models) amphibious excavator manufacturer by volume in South East Asia with worldwide recognition for our quality and superior performance.

SHOT BLASTING

Pontoons are shot blasted to ensure that the surface is thoroughly clean and free from contaminants and rust. In addition, this process presents the steel with a surface texture that provides excellent adhesion of prime coat of paint.

HYDRAULIC EXTENDABLE PONTOONS

An optional design feature allows each pontoon to retract or extend outward hydraulically. A fully retracted pontoons with reduced footprint provides the added advantage and convenience of transporting the machine on trailer without dismantling into modules. A tremendous saving on logistical cost over time. Fully extended pontoons provides the extra stability when situation call for.

The hydraulic control is totally independent (non shared) from the existing hydraulic circuit. We have an upgrade kit where an auxiliary hydraulic function can be added with full control from the operator cabin. Click on the video for details.

SUPPLEMENTARY PONTOONS AND SPUDS

Supplementary pontoons can be easily attached onto the outer side of the primary pontoons to enhance stability. The hydraulic-mechanical spuds system which is control from the operator cabin is a superb solutions to overcome buoyancy in deep water, providing additional stability and enhanced operability on water up to 4 meters deep.

Users can chose to add the supplementary pontoons and spuds system at the later stage when need arises. Auxiliary hydraulic lines are preinstalled on all primary pontoons whereby the user can simply installed without tedious modification. A truly plug-and-play system and future proof in design.

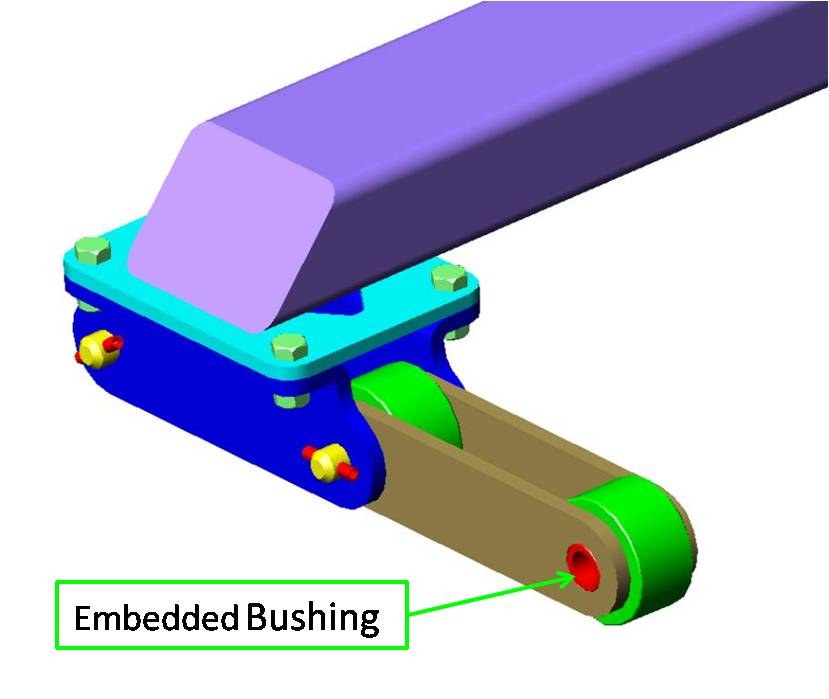

TRACK CHAIN

One of the most critical components of the undercarriage system, it is entirely in-house design and manufacture, to ensure proper quality control. One of the criterion of a good design is that the track chain has to perform reliably under various working conditions. Special grade steel is used and precisely trimmed to extremely tight tolerance. Each roller has an embedded induction hardened bushing that greatly prolongs the useful working life of the track chain.

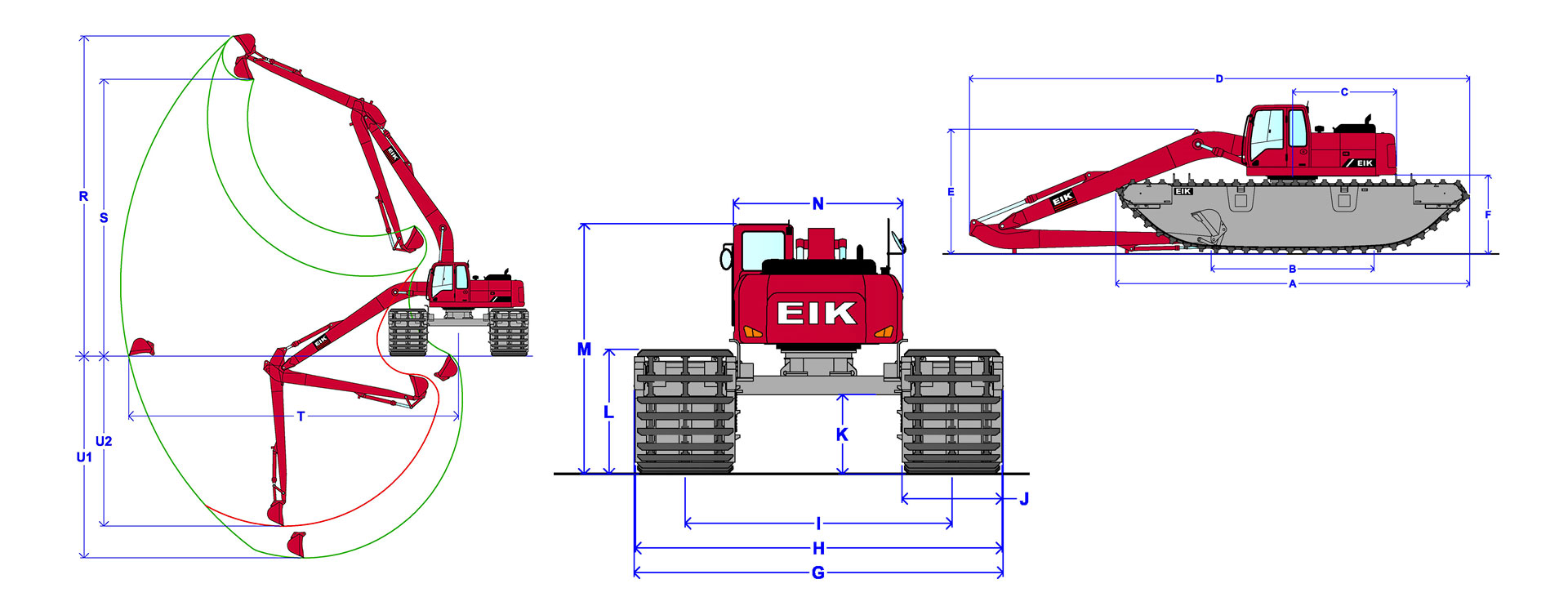

Here are the key specifications for this product model.

Want to know more? Download the brochure or contact us.

| Amphibious Undercarriage Models | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

AM60-1ER |

AM70-1ER |

AM80-5ER |

AM140-5ER |

AM200-6ER |

AM250-4ER |

AM300-2 |

AM350-3 |

AM400-3 |

AM450-1B |

||

Dim.(ft&in) |

Description |

For 7,700 - 9,900 lbs excavator |

For 11,000 - 13,200 lbs excavator |

For 15,400 - 17,600 lbs excavator |

For 26,400 - 30,800 lbs excavator |

For 44,000 - 50,600 lbs excavator |

For 61,600 - 66,000 lbs excavator |

For 85,800 - 94,600 lbs excavator |

For 72,600 - 83,600 lbs excavator |

For 85,800 - 94,600 lbs excavator |

For 96,800 - 105,600 lbs excavator |

| A | Max. Track Length | 18' 3" ft | 21' 2" ft | 22' 9" ft | 30' 6" ft | 31' 6" ft | 31' 6" ft | 35' 5" ft | 38' 9" ft | 38' 7" ft | 38' 5" ft |

| B | Track Length On Ground | 9' ft | 9' 6" ft | 10' 6" ft | 14' 9" ft | 14' 9" ft | 14' 9" ft | 17' 1" ft | 18' 8" ft | 18' 8" ft | 19' 8" ft |

| C | Rear Upper Structure Length | 2' 9" ft | 5' 2" ft | 5' 9" ft | 7' ft | 9' 4" ft | 9' 10" ft | 10' 6" ft | 11' 6" ft | 11' 6" ft | 11' 8" ft |

| D | Overall Length | 25' 11" ft | 24' 6" ft | 30' 4" ft | 40' 2" ft | 44' 5" ft | 47' 3" ft | 51' ft | 54' 5" ft | 56' 5" ft | 59' ft |

| E | Height of Boom | 7' 10" ft | 7' 6" ft | 9' 6" ft | 9' 8" ft | 11' 5" ft | 11' 8" ft | 13' 5" ft | 13' 6" ft | 14' 1" ft | 14' 1" ft |

| F | Counterweight Clearance | 5' ft | 5' 4" ft | 5' 8" ft | 6' ft | 7' 1" ft | 7' 3" ft | 7' 9" ft | 7' 9" ft | 7' 10" ft | 7' 10" ft |

| G | Overall Width, min/max(outwardly extendable) | 9' 1"/11' 5" ft | 9' 3"/11' 11" ft | 11' 1"/13' 9" ft | 13' 2"/16' 10" ft | 14' 9"/19' 7" ft | 17' 2"/21' 11" ft | 19' 6"/22' 9" ft | 19' 8"/22' 11" ft | 19' 10"/23' 2" ft | 21' 1"/24' 5" ft |

| H | Undercarriage Width, min/max | 9'/11' 4" ft | 9' 1"/11' 8" ft | 11'/13' 8" ft | 12' 11"/16' 6" ft | 14' 8"/19' 6" ft | 17' 1"/21' 9" ft | 19' 5"/22' 8" ft | 19' 7"/22' 10" ft | 19' 8"/23' ft | 21'/24' 3" ft |

| I | Track Gauge, min/max | 5' 9"/8' ft | 5' 9"/8' 5" ft | 6' 9"/9' 5" ft | 8' 2"/11' 9" ft | 9' 4"/14' 2" ft | 10' 9"/15' 6" ft | 13' 1"/16' 4" ft | 13' 2"/16' 7" ft | 13' 3"/16' 7" ft | 13' 11"/17' 3" ft |

| J | Track Cleat Width | 3' 3" ft | 3' 3" ft | 4' 3" ft | 4' 9" ft | 5' 4" ft | 6' 4" ft | 6' 4" ft | 6' 5" ft | 6' 5" ft | 7' 1" ft |

| K | Min. Ground Clearance | 3' 4" ft | 3' 3" ft | 3' 9" ft | 3' 8" ft | 4' 3" ft | 4' 3" ft | 4' 3" ft | 3' 8" ft | 3' 10" ft | 3' 10" ft |

| L | Track Height | 4' 9" ft | 5' ft | 5' 5" ft | 5' 7" ft | 6' 8" ft | 6' 8" ft | 6' 8" ft | 6' 8" ft | 7' 3" ft | 7' 3" ft |

| M | Overall Cab Height | 11' 4" ft | 11' 8" ft | 12' ft | 12' 4" ft | 13' 5" ft | 13' 6" ft | 14' ft | 14' 1" ft | 14' 1" ft | 14' 4" ft |

| N | Upper Structure Overall Width | 4' 11" ft | 6' 5" ft | 7' 5" ft | 8' ft | 8' 4" ft | 9' 4" ft | 9' 9" ft | 9' 10" ft | 10' 2" ft | 11' 7" ft |

| R | Max. Cutting Height | 21' 4" ft | 23' 4" ft | 26' 1" ft | 37' 5" ft | 40' 8" ft | 44' 11" ft | 47' 11" ft | 50' 2" ft | 49' 10" ft | 53' 8" ft |

| S | Max. Loading Height | 17' ft | 18' 10" ft | 20' 8" ft | 30' 6" ft | 34' 5" ft | 37' 5" ft | 39' 8" ft | 42' ft | 41' 8" ft | 45' 3" ft |

| T | Recommended Outreach | 23' ft | 23' ft | 26' 3" ft | 39' 4" ft | 45' 11" ft | 49' 3" ft | 52' 6" ft | 55' 9" ft | 59' 1" ft | 65' 7" ft |

| U1 | Max. Digging Depth from Front | 12' 2" ft | 11' 6" ft | 12' 6" ft | 23' 11" ft | 29' 2" ft | 30' 10" ft | 32' 6" ft | 36' 1" ft | 41' ft | 45' 7" ft |

| U2 | Max. Digging Depth from Side | 11' 6" ft | 11' 6" ft | 11' 2" ft | 21' 4" ft | 23' 7" ft | 23' 7" ft | 27' 11" ft | 31' 6" ft | 34' 1" ft | 37' 1" ft |

| Bucket Capacity | 0.14 yard³ | 0.17 yard³ | 0.34 yard³ | 0.46 yard³ | 0.65 yard³ | 0.85 yard³ | 1.05 yard³ | 1.18 yard³ | 1.31 yard³ | 1.31 yard³ | |

* The above specifications are for reference only, actual working range may vary from machine models.

** For the benefit of continuous product improvement, specifications are subjected to change without prior notice.

The high performance amphibious excavator is powered by our patented ‘multi-synchronous hydraulic motor direct drive’ system, the pivotal technology that positions EIK at the forefront of amphibious excavator design.

The undercarriage design offers extremely low ground pressure, making it the only undercarriage system that allows an excavator to work on swamps and soft terrain.

It is also designed to be able to float on water as a safety feature.

- Direct drive system that minimise mechanical loses of power.

- Swampy areas are not necessary flat, and one will realize its full potential when tracking on uneven and high viscosity and muddy terrains.

- Motors mounted on front and rear running in synchronous mode provide both push and pull action, offering superior tracking ability.

- No modification to the main pump or hydraulic system of your existing excavator is required to accommodate the multi-synchronous drive system.

Maintenance and cleaning of waterways, lakes, shorelines, ponds, etc

Erosion control and prevention

Flood protection and flood maintenance works

Deepening of waterways and river deltas

Maintenance and repair of natural environment

Landscape building and protection

Accessing difficult strands of water/soft terrain

Swamp and wetland construction

Road building through wetlands

Cleaning of tailing dam in mining operation

- Heavy duty in construction.

- Design is simulated extensively, ensuring design integrity and detecting potential stress and fatigue points.

- All surfaces are shot blasted.

- Uses marine grade epoxy paint as undercoat.

- All surfaces are shot blasted.

- All surfaces are shot blasted.

- Uses marine grade epoxy paint as undercoat.

You Might Also Like

FIND YOUR RIGHT SOLUTION WITH EIK ENGINEERING

At EIK Engineering, we are committed to the delivery of quality amphibious excavators and excavator attachments. Please fill out the form below to get in touch with us! We’ll get back to you as soon as we can.