AMPHIBIOUS SERIES

Amphibious Carrier

Want to know more? Download the brochure or contact us.

EIK Amphibious carrier, also known as amphibious transporter is specifically designed to work in a marshy, swampy area, soft terrain, and open water. The amphibious carrier consists of an EIK undercarriage with 3 beams and 1 center frame, upper structure with cabin, engine, and platform. The innovative engineering of undercarriage allows customization for various needs. The platform can be designed to fit the different models of EIK undercarriage. It could be used for a wide range of purposes including transporting passengers and equipment.

SHOT BLASTING

Pontoons are shot blasted to ensure that the surface is thoroughly clean and free from contaminants and rust. In addition, this process presents the steel with a surface texture that provides excellent adhesion of prime coat of paint.

SUPPLEMENTARY PONTOONS AND SPUDS

Supplementary pontoons can be easily attached onto the outer side of the primary pontoons to enhance stability. The hydraulic-mechanical spuds system which is control from the operator cabin is a superb solutions to overcome buoyancy in deep water, providing additional stability and enhanced operability on water up to 4 meters deep.

Users can chose to add the supplementary pontoons and spuds system at the later stage when need arises. Auxiliary hydraulic lines are preinstalled on all primary pontoons whereby the user can simply installed without tedious modification. A truly plug-and-play system and future proof in design.

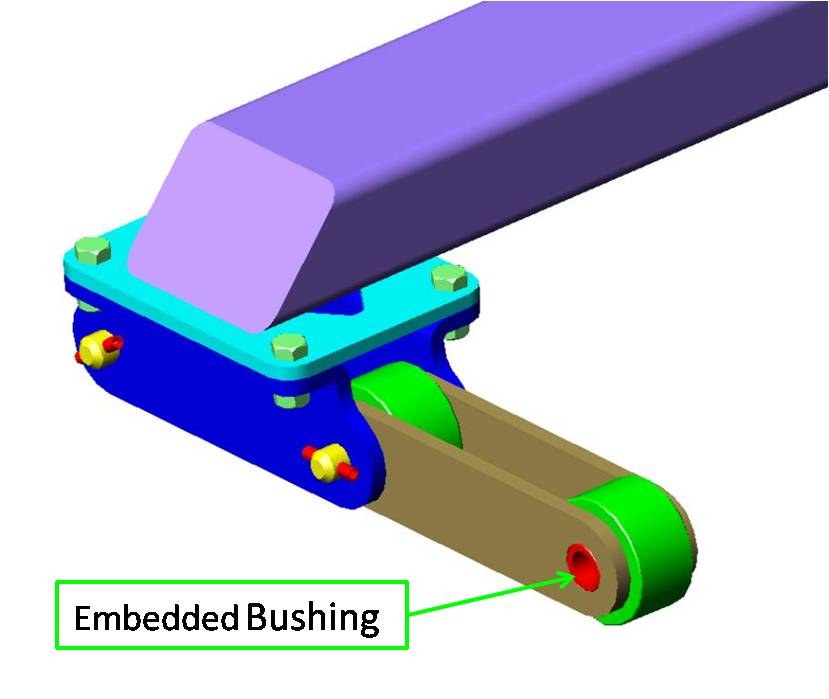

TRACK CHAIN

One of the most critical components of the undercarriage system, it is entirely in-house design and manufacture, to ensure proper quality control. One of the criterion of a good design is that the track chain has to perform reliably under various working conditions. Special grade steel is used and precisely trimmed to extremely tight tolerance. Each roller has an embedded induction hardened bushing that greatly prolongs the useful working life of the track chain.

The high performance amphibious excavator is powered by our patented ‘multi-synchronous hydraulic motor direct drive’ system, the pivotal technology that positions EIK at the forefront of amphibious excavator design.

The undercarriage design offers extremely low ground pressure, making it the only undercarriage system that allows an excavator to work on swamps and soft terrain.

It is also designed to be able to float on water as a safety feature.

- Direct drive system that minimise mechanical loses of power.

- Swampy areas are not necessary flat, and one will realize its full potential when tracking on uneven and high viscosity and muddy terrains.

- Motors mounted on front and rear running in synchronous mode provide both push and pull action, offering superior tracking ability.

- No modification to the main pump or hydraulic system of your existing excavator is required to accommodate the multi-synchronous drive system.

Transportation of passenger, cargo, equipment

- Heavy duty in construction.

- Design is simulated extensively, ensuring design integrity and detecting potential stress and fatigue points.

- All surfaces are shot blasted.

- Uses marine grade epoxy paint as undercoat.

You Might Also Like

FIND YOUR RIGHT SOLUTION WITH EIK ENGINEERING

At EIK Engineering, we are committed to the delivery of quality amphibious excavators and excavator attachments. Please fill out the form below to get in touch with us! We’ll get back to you as soon as we can.